Among the chestnut trees of factory 4.0, artificial intelligence appears as THERE source of earnings.

According to BCG, organizations that adopt and integrate AI are better equipped and will double their cash flow by 2030. Yeah.

The truth is that currently only 55% of industrial companies are starting to develop AI projects, internally or via simple applications.

However, its advantages are numerous: quality management (reduction of quality control costs and optimization of maintenance), reporting and analysis of data patterns in real time, etc.

Let's take the example of optimizing maintenance time: on average, a factory loses 5% of productivity during machine downtime (and this can easily go up to 20%). This mechanically leads to difficulty in meeting production objectives, late customer deliveries, loss of income, mobilization of resources linked to the resolution of the problem or even costs due to overtime, to name just a few. some.

According to McKinsey, for industry, the greatest added value of AI today comes from its use for predictive maintenance ($500 to 700 billion in the global economy).

According to the firm, companies that use AI and machine learning for product defect detection and quality testing can increase factory productivity by up to 50%, generating up to $2 trillion. of value in supply chain management and production.

So why are so few industrialists taking the risk?

Cost of user training and available tools:

Businesses do not master development and do not benefit from a simple and secure application where they can iterate and exchange with technical users.

Technical cost:

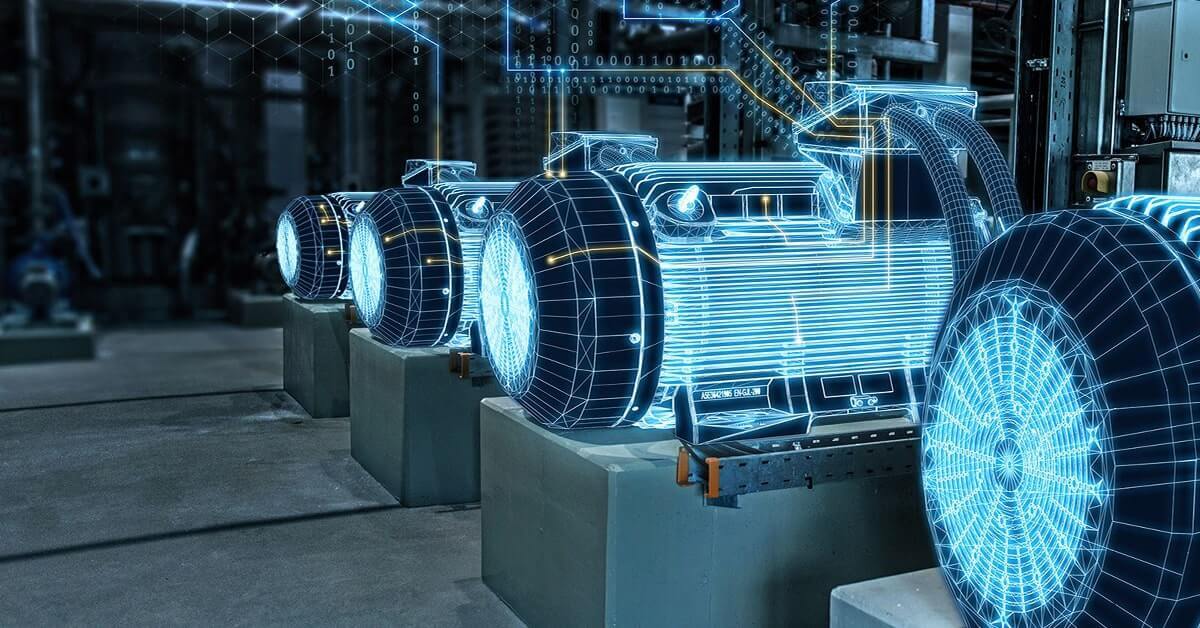

Too many different systems to connect to improve prediction. Indeed, if the data coming from IoT sensors is essential for predictive maintenance (vibrations, temperature changes for example), other data sources can be included to further refine the prediction:

- Location data

- Manual data via human control

- MES data

- Static data

- Equipment usage history

- External data via APIs

- Data from programmable control equipment

Okay, but how to go about it then?

You must have the ability to collect this different data and correlate it on a data platform. This platform must be able to do data science and if possible in low-code so that non-tech people can work with tech people on these subjects, without friction. Indeed :

- This allows connectivity to many data sources

- There is no limit on the quantity and complexity of data

- The platform is inclusive: easy to use, regardless of technical background and therefore allows you to free yourself from the supplier and improve data analysis opportunities.

- It is adapted to the “small steps” method: it does not limit teams to a single use case but rather allows them to start with one case and scale up by integrating machine learning and AI.

So if we recap:

Predictive maintenance is a strategic issue for factories.

Its implementation within the workshop is therefore essential and the integration of a edge solution allowing the reporting of machine data in real time is a prior.

The platform must be able to retrieve data from various systems, THE all without coding to enable adoption in the factory And there skill development of employees.

If you want to discuss these topics with us or discover Niagara Edge, do not hesitate to contact us via the live chat on your right or here !